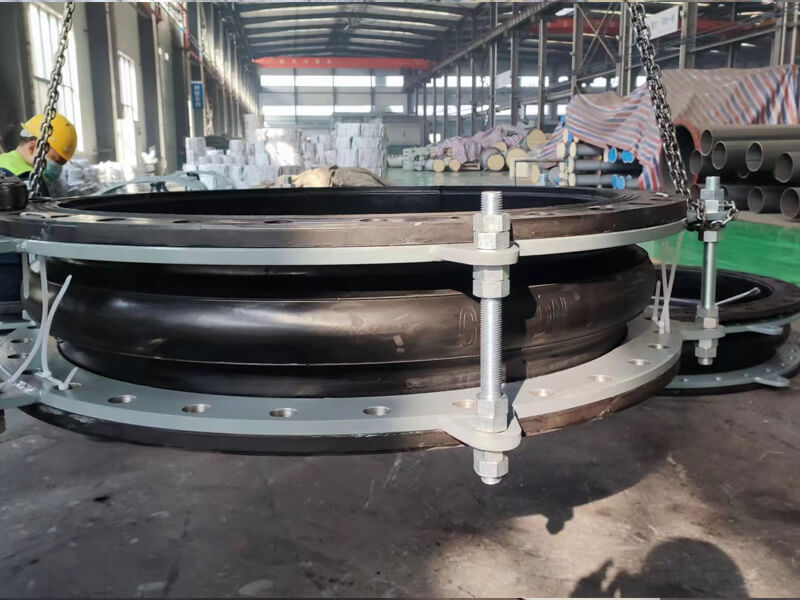

Ethylene Propylene Diene Monomer (EPDM) rubber expansion joints, often referred to as EPDM rubber joints, are essential components in piping systems. They address the challenges posed by temperature fluctuations, vibrations, and pressure changes, offering a solution to thermal expansion, contraction, and stress issues within pipelines. The term “Ethylene Propylene Diene Monomer” denotes the primary material used in these joints.

Key characteristics of EPDM rubber expansion joints include:

1.Excellent Weather Resistance:

EPDM rubber excels in outdoor and harsh weather conditions. It withstands the effects of UV radiation, oxygen, oxidation, and humidity, thereby extending its operational life.

2.Superior Chemical Resistance:

EPDM rubber can endure a variety of chemicals such as acids, alkalis, oxidizing agents, and certain solvents. This adaptability suits it for diverse industrial settings.

3.Elasticity and Flexibility:

EPDM rubber expansion joints retain their elasticity and flexibility during temperature changes and pressure fluctuations. This property allows them to absorb thermal expansions, contractions, and vibrations within the piping system, alleviating stress and preventing damage.

4.Effective Sealing Properties:

EPDM rubber joints exhibit excellent sealing capabilities, effectively preventing fluid leakage and ensuring the safety and reliability of the piping system.

EPDM rubber expansion joints find widespread applications in heating, ventilation, and air conditioning (HVAC) systems, water treatment facilities, chemical processing plants, construction projects, and other areas where compensating for pipe movement and absorbing vibrations is crucial. They provide both flexibility and reliability to piping systems, contributing to their prolonged lifespan and the seamless continuity of operations.

Post time: Aug-16-2023