Summary : On April 3, 2016, our partner from Bangladesh, South Asia, took a field visit to Lanphan factory to check and accept bellows expansion joint. They thought highly of our bellows as well as our professional standards.

BPDP(Bangladesh Power Development Board) is a statutory body created on May 1, 1972. After decades of development, BPDP increased its installed generation capacity from 200MW to 12339MW until April, 2016. BPDP is responsible for major portion of generation and distribution of electricity in urban areas except Dhaka and west zone of the country. It’s our great honor to be a cooperative partner with BPDP during the process of capacity expansion---supplying non-standard bellows expansion joint to BPDP.

1.Product Inspection

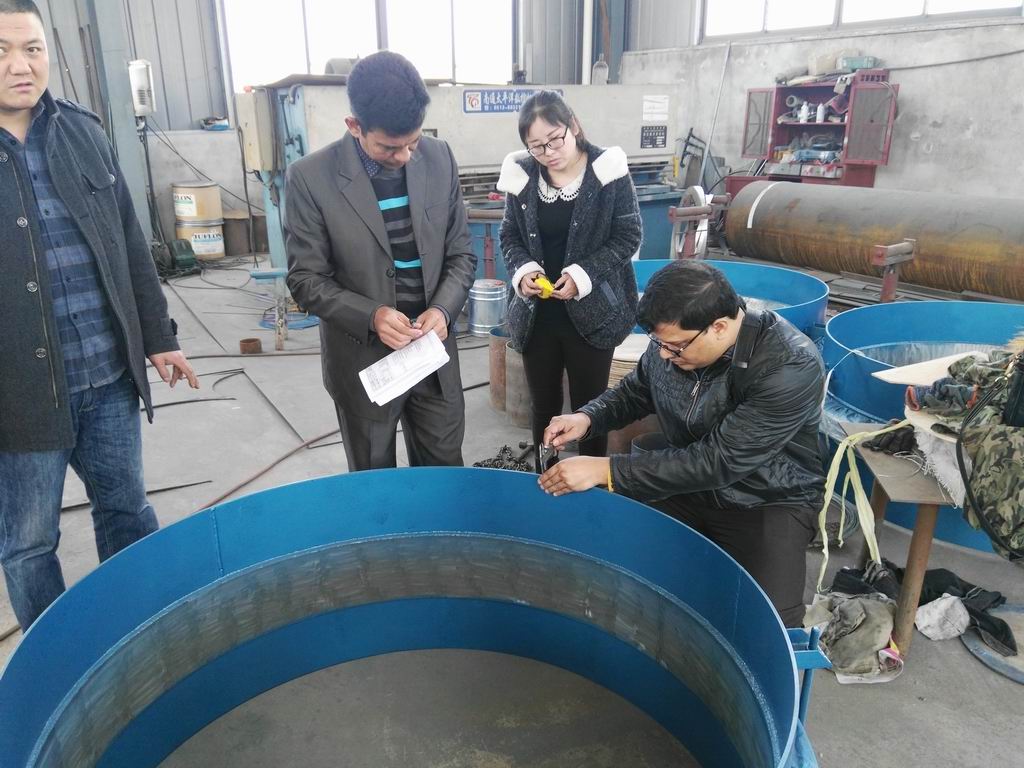

On April 3, 2016, our partner form Bangladesh, South Asia, took a field visit to Lanphan factory to check and accept bellows expansion joint. Holding the working attitude of safety production, rigorous and pragmatic at work, clients measured bellows expansion joint’s dimension carefully according to drawing. They were extremely strict with product dimension, as for every dimension shown in drawing, they measured the thickness of bellow’s welding end pipe, as well as outside and inside diameter of bellows compensator by vernier caliper and tape for at least 3 times. Our products owns a high quality standard which is amenable to any strict inspection, clients were very satisfied with measuring result and signed name and date in every expansion compensator.

2.Detail Confirmation

Before signing order, our business manager Macey Liu had a detailed communication with clients, optimized the drawing of bellows expansion joint, and perfectly solved following controversial questions.

The bellows is single-layer or double-layer?

The purchased bellows expansion joint will apply to pressure-bearing pipeline in power plant, its regulated pressure is 10KG, which belongs to middle-low pressure, overall considered from the aspect of economic benefit, we recommend the single-layer bellows compensator has lower price to clients.

Can the welding end pipe and waves use inside welding method?

In earlier drawing, clients required inside welding of wave and welding end pipe, wave is inside and welding pipe is outside, in order to prevent that when bellows being compressed, moving down of welding pipe cause damage to waves. For client’s question, our engineer provides a professional answer.

Firstly, the needed bellows of clients has internal diameter of 1400mm, end pipe thickness of 8mm, external diameter of 1416mm, while the national standard of bellows diameter is 1420mm, that is unreality to do inside welding; besides, it’s entirely enough of the welding stiffness, if the suddenly compress makes connecting pipe dislocate, bellows compensator will damaged, no matter inside welding or outside welding, that won’t happen.

Based on above reasons, we finally choose outside welding method that welding pipe is inside and wave is outside.

3.Other Requirements

①Setting of lifting trunnion

When lifting bellows expansion joint, clamping welding pipe wall will damage the spraying of welding pipe and affect anti-corrosion effect, according to client request, we’ll add lifting trunnion device in later design and production.

②Nameplate and shipping mark

For nameplate and shipping mark in products, clients also have their specific requirements: can not nail the nameplate, pasting is the only method to fix their nameplates, and contents on nameplate is strictly according with client needs.

4.Project Summary

Each project has its own characteristics, no matter small or big order amount, we all treat it with patience and earnest. In this project, we made following endeavor:

Constantly think from client’s perspective, save cost and increase benefit for clients;

Communicate more with clients, try our best to satisfy their reasonable request;

Strictly according with standards to manufacture products, amenable to any inspection of clients;

Rationally use in-house technical advantages, offering better advice for clients.

Indeed, we still have insufficient in this project, we will accept client’s advises and make improvements in product design and production.

When clients finishing goods inspection, our engineer spoke highly of them, said that they’re the most rigorous clients he’d ever seen---clients measured every detail, every size for at least 3 times to make sure product is undamaged and qualified. Facts proves that our products can stand any inspection, clients thought highly of our products as well as our professional standards. Meanwhile, clients expressed that it was a pleasure cooperation, they will sign more orders with us in future. Client’s affirmation is our biggest success, and it exactly manifesting our goal: offering better products and better service for clients!

Post time: Feb-23-2023